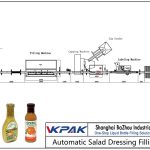

Garis Pengisi Cairan Dishwashing otomatis

- Dishwashing liquid is high foaming mixture which creates lots of foam upon the collision of the liquid to each other in pressure. To fill such high foamy products, we have developed semi automatic we all as fully automatic dishwashing liquid filling machines to match clients requirement. They are filled at very low speed with dive In the nozzles inside the bottle to lower down the pressure at the time of filling. Special neck holding bottle guides are also provided in case of a very light weighted bottle. Filling the product with the help of the VKPAK’s filling machine will provide a clean, leak proof, reliable and consistent operation.

- Pambuka Ringkes:

- Mesin Isi iki minangka mesin ngisi volumetrik sing cocog kanggo ngisi beda-beda cairan kelikatan. Mesin digawe dening struktur linear, kuantitas sirah bisa digawe miturut panjaluk kaya 4/6/8/10/16 kepala.

- Sistem pangisi didorong motor servo sing njamin akurasi sing diisi kanthi dhuwur. Iki dikendhaleni dening PLC, antarmuka manungsa lan operasi gampang.

- Mesin Utama Kalebu:

- Botol Dipakani Botol

- Mesin Seret Piston otomatis

- Mesin Capping otomatis

- Mesin Label Lekat Otomatis otomatis Loro

- Jinis Botol Nggulung Botol

- Fitur:

- Digawe kanthi baja tahan karat 304 sing paling dhuwur.

- Ora ana botol tanpa isi.

- Bisa ngontrol kecepatan ngisi beda ing dosis siji.

- Sistem ngisi dikendhaleni nganggo motor servo, mula bisa njamin akurasi sing diisi.

- Kepala ngisi nyilem kasedhiya miturut produk sing beda (Kanggo pilihan).

- Umpan udara ngeculake nozzle kasedhiya kanggo produk lengket supaya ora kena untune buntut

- Tray produk bisa kasedhiya yen ana bocor saka nozzle (Kanggo pilihan).

- Bisa ngirit nganti 20 kelompok paramèter ing PLC, trep kanggo operasi.

- Ora ana tooling sing kudu diganti liwat macem-macem botol ukuran.

- Ngatur bagean sambungan kanthi cepet, gampang dibubarake lan mesin sing jelas.