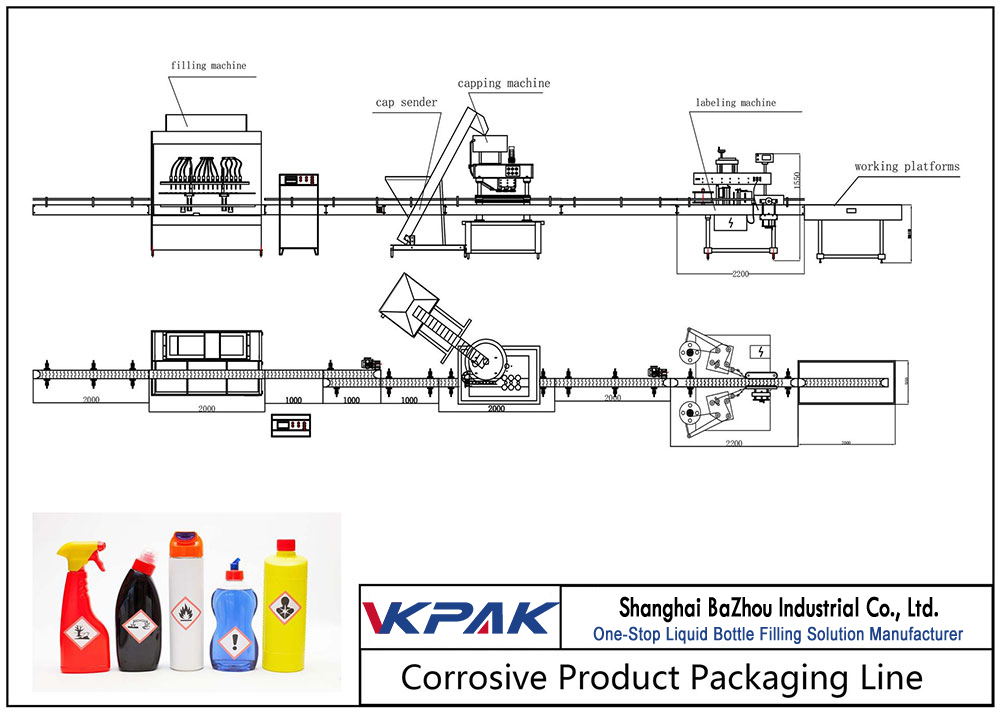

Garis Pengisi Produk Korosif Otomatis

- The VKPAK Automatic Corrosive Filler (ACF) is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery. The speed and ease of use make the ACF an ideal solution for chemical plants producing acids, bleach, ammonia, as well as food plants filling aggressive brine solutions. Each ACF machine is built from corrosive resistant material custom suited to the product they are intended for. They include a 10’ variable speed conveyor built from the same corrosive resistant components.

- Pengisi Otomatis Otomatis uga kalebu tampilan layar tutul warna digital kanthi memori kerja, ora ana botol, isi utawa langkah pangisi, lan kontol botol total. Sistem ACF gampang disiyapake, digunakake, lan nyetel latihan minimal. Pilihan uga kabeh model pnematic uga kasedhiya.

- Mesin Utama Kalebu:

- Mesin Ngisi Cairan Otomatis

- Mesin Capping otomatis

- Mesin Labeling otomatis

- Mesin Pengeduksi Induksi otomatis

- Mesin panyegelan Carton otomatis

- Mesin Cartonning Otomatis

- VKPAK supplies a complete range of equipment to fill corrosive products to meet nearly any application. Made from HDPE (high density polyethylene, these filling machines, conveyors and turntables are designed to handle the punishment of a highly corrosive environment where standard metal components would normally dissolve.

- VKPAK poly filling systems use volumetric filling methods, which are extremely accurate and versatile. The fillers are designed to fill from a fraction of an ounce up to five gallons and are capable of handling viscosities ranging from thin and foamy to very thick liquids. VKPAK’s modular design can allow the design of the filler machines to have multiple tanks and fill head assemblies to isolate non-compatible products within a common frame. All VKPAK fillers are built to provide the best combination of maximum versatility, easy setup and changeover, and minimal down-time for maintenance and cleaning. VKPAK also manufactures this type of bottling equipment for table-top applications.

- Fitur utama lan fitur struktur:

- 1. Sistem kontrol - kanthi sistem kontrol Mitsubishi PLC, ngisi dosis tuning acak

- 2. Antarmuka operasi - antarmuka layar sing warni, antarmuka manungsa-mesin gampang, aman lan bisa dipercaya

- 3. Fitur Fitur - Motong nganggo piranti anti-netes, bisa nyilem kanggo ngisi bahan. (Fitur iki bisa dipilih)

- 4. Komponen listrik - nggunakake merek internasional sing misuwur supaya peralatan kasebut bisa dipercaya lan akurasi dhuwur.

- 5. Komponen mekanik - bagean utama digawe saka pigura PP sing berkualitas tinggi, bagean kontak digawe saka gel silika silika sing ora beracun, selang PTFE, katup yaiku PVC.

- 6. Ekstensi - bisa disesuaikan kanggo syarat konfigurasi spesifik, kayata: bahan sing ditutup, dadi panas, sterilisasi, lsp.

- 7. Ngitung count - count nyata-wektu, nggambarake output karya langsung.

- 8. Deteksi Pengisian - Ora ana botol, utawa nalika nomer ngisi botol ora cukup, ora ana punane

- Parameter Teknis

| Spesifikasi sing bisa ditrapake | 100-5000ml |

| Kapasitas produksi | 1000-2500 botol / jam (4/8/12/16 ngisi sirah) |

| Akurasi ngisi | ± 1% |

| Capping rate | ≥99% |

| Pasokan tenaga | 380V / 50Hz |

| Kuwasa | 2.5kW |

| Ukuran total | 2500 * 900 * 2500MM |